Natural PVA Dissolvable Filament, Water Soluble Support 1.75mm, -0.5kg/1.1lbs, Accuracy +/- 0.05mm

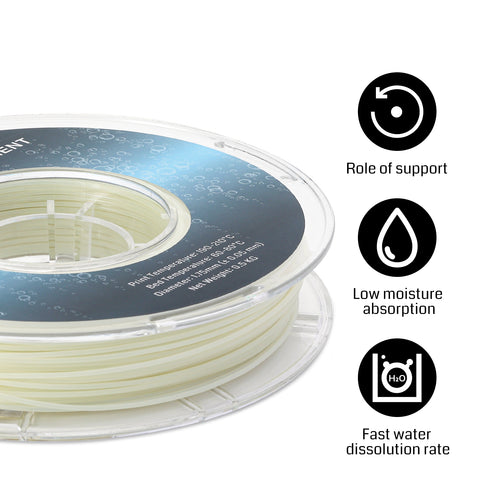

- Faster Dissolution Rate: PVA filament begins to dissolve after 1-2 minutes in water at 50°C.

- Creative Freedom: Sainsmart PVA filament provides stable support to complex designs, even those with features like cavities, and intricate internal details.

- Compatible with PLA: PVA is used in conjunction with PLA not ABS because it adheres well to PLA. The extrusion temperature difference can also be problematic with ABS.

- Printing Setting: Recommended Extrusion/Nozzle Temperature 190ºC- 210ºC (212ºF - 410ºF); Recommended bed Temperature 60ºC- 80ºC (140ºF - 176ºF).

- Package: PVA 3D Printer Filament Vacuumed Sealed With Desiccant.

PVA is a water-soluble synthetic polymer. PVA is degradable and dissolves quickly in water. It is the perfect filament to use as a support material for its dissolvable properties. Also, the quality of filament is of great quality, and no kinks or breaks. Designed for dual extrusion 3D printers. Best choice for perfect printing!

Faster dissolution

Different from ordinary PVA, our premium PVA filament can be dissolved by soaking in water at 50°C for 1-2 minutes.

Creative Freedom

Sainsmart PVA filament provides stable support to complex designs. No more imperfections from traditional non-dissolvable support structures.

No Special Solvents Required

Fused Materials PVA does not require special solvents or tools. Wait for it to dissolve the support of your print after 1-2 minutes in water at 50°C.

SPECIFICATION

- Density: 1.27 g/cm³

- Tensile Strength: 14 MPa

- Recommended Printing Temp.: 190ºC- 210ºC (212ºF - 410ºF)

- Recommended bed Temp.: 60ºC- 80ºC (140ºF - 176ºF)

Compatible 3D Printers: All FDM 3D Printers PIXMA MG5420 Replicator 2 Ultimaker 1 RepRap Replicator 2x Prusa i3 Mendel Prusa Ultimaker 2 Replicator Print/bot Leapfrog Creatr Zcorp Solidoodle UP! Plus Form 1 Cube X Up! Mini Creator Mende! Max uPrint PowerWasp Dimension Lulzbot Felix 2. 0

Let's See How PVA Support

Notice

-Generally, PVA is used in conjunction with PLA not ABS because it adheres well to PLA. The extrusion temperature difference can also be problematic with ABS.

-Importantly, PVA should not be allowed to sit at temperatures higher than 200°C for an extended period of time, known as pyrolysis, it will form jams that are extremely difficult to remove. Unlike PLA and ABS, you cannot remove the jam by increasing the temperature.

-Clearing the jam in the nozzle will often require it to be re-drilled or replaced altogether, so be careful!