What Makes The 3DPrintMill Special

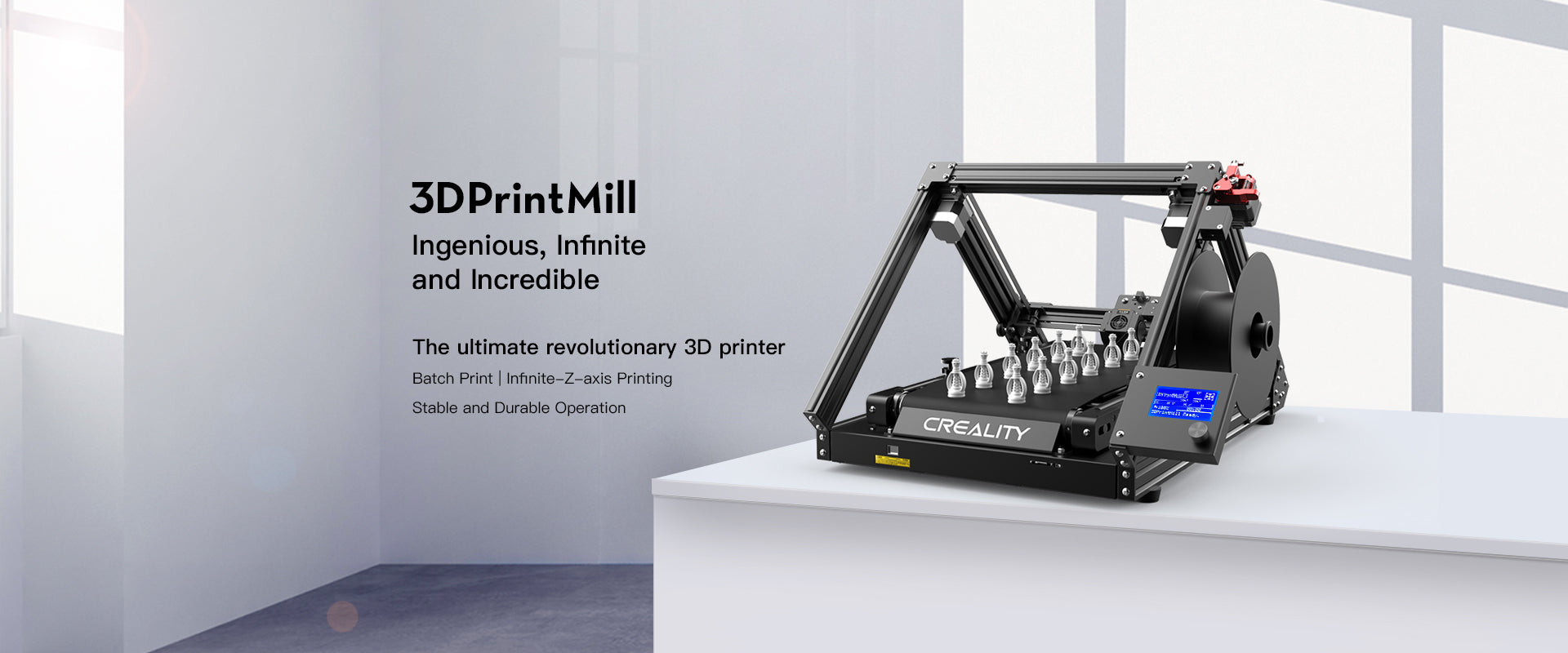

The 3DPrintMill (Creality CR-30) is a cross between a traditional 3D printer and a conveyer belt. With its conveyor-belt style print bed and 45° printing angle, this innovative belt printer allows you to print continuously, which makes printing long props in one-piece and batch printing possible. In addition, you can also print perfect unsupported overhangs with the printer. If you are running a 3D Print Farm to do mass production or if you are a cosplay enthusiast looking for a printer to print the costumes, the CR-30/3D PrintMill is definitely worth trying.

Reviews on Youtube

Specifications

| Print Tech | FDM | Print Size | 200*170*∞mm |

| Product Dimension | 535*656*410mm | Package Size | 685*565*302mm |

| Weight | 16.5kg | Gross Weight | 20.5kg |

| Slicing Software | Crealitybelt | Printing Precision | ±0.1mm |

| Nozzle Diameter | 0.4 mm | Nozzle Qty | 1 |

| Hot Bed Temp. | ≤ 100℃ | Nozzle Temp. | ≤ 240 ℃ |

| Layer Height | 0.1-0.4mm | Max Power Consumption | 350W |

| Support Materials | PLA/TPU/PETG | FIalment Diameter | 1.75mm |

| Power Requirement | AC 100-120V / 200-240V, DC 24V | ||

![[Discontinued] Creality 3DPrintMill Belt 3D Printer, Infinite-Z-axis printing](http://www.sainsmart.com/cdn/shop/products/51TlXITTktS._SL1000.jpg?v=1641462382&width=1445)

![[Discontinued] Creality 3DPrintMill Belt 3D Printer, Infinite-Z-axis printing](http://www.sainsmart.com/cdn/shop/products/CR-30_CN-2.jpg?v=1641462382&width=1445)

![[Discontinued] Creality 3DPrintMill Belt 3D Printer, Infinite-Z-axis printing](http://www.sainsmart.com/cdn/shop/products/CR-30_CN-3.jpg?v=1641462382&width=1445)

![[Discontinued] Creality 3DPrintMill Belt 3D Printer, Infinite-Z-axis printing](http://www.sainsmart.com/cdn/shop/products/CR-30_CN-4.jpg?v=1641462382&width=1445)

![[Discontinued] Creality 3DPrintMill Belt 3D Printer, Infinite-Z-axis printing](http://www.sainsmart.com/cdn/shop/products/CR-30_CN-5.jpg?v=1641462382&width=1445)