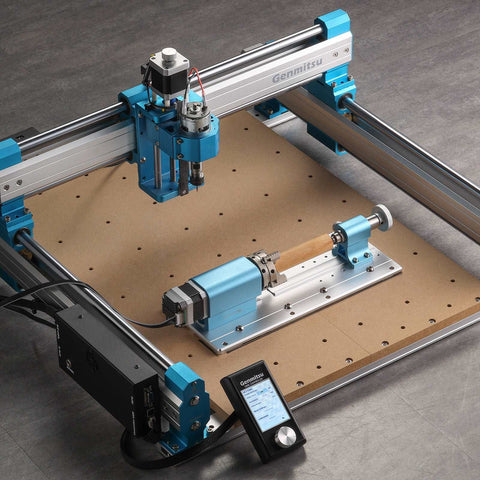

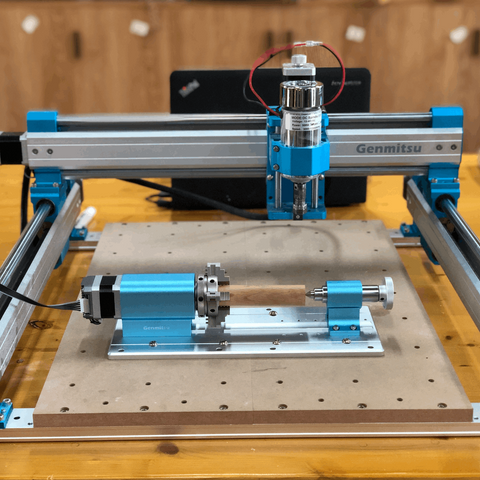

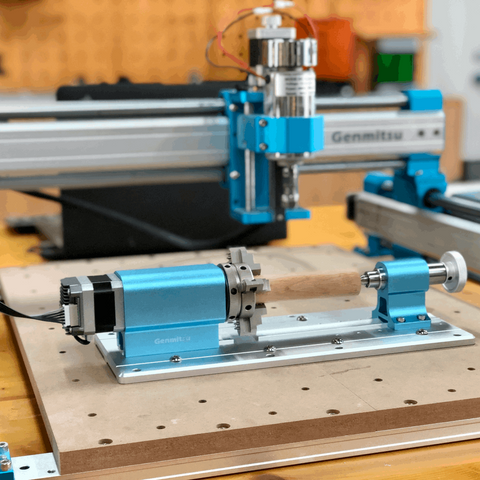

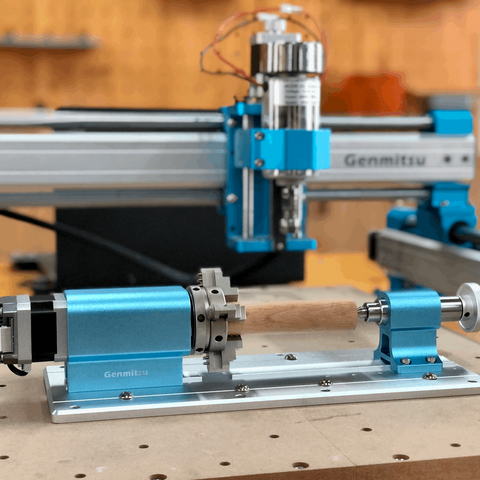

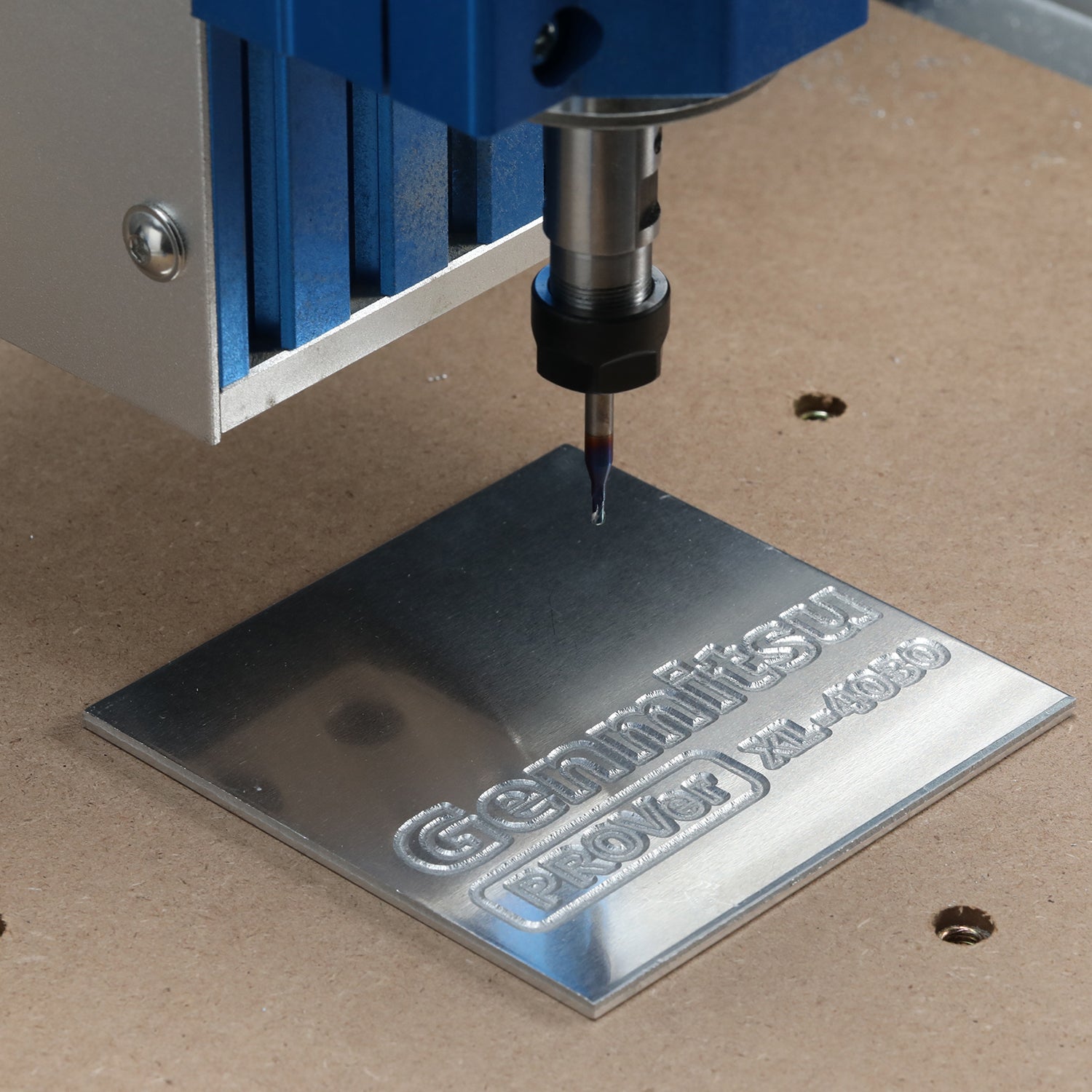

4th Axis CNC Rotary Module Kit for 4040-PRO, 3030-PROVer MAX

Extra 15% OFF

Superior Performances

Precise Control

Simple Length Adjustment

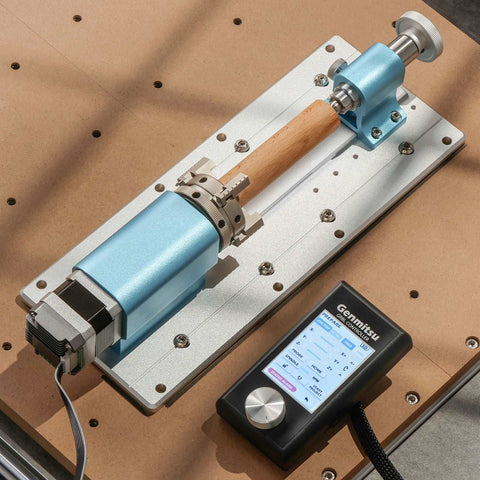

Software & Controller

Review

Specifications

| Compatible CNC Machine | 4040-PRO, 4040-PRO MAX, 4040 Reno, 3030-PROVer MAX CNC Router |

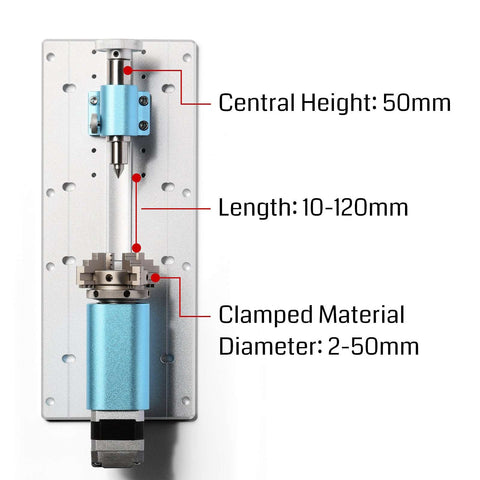

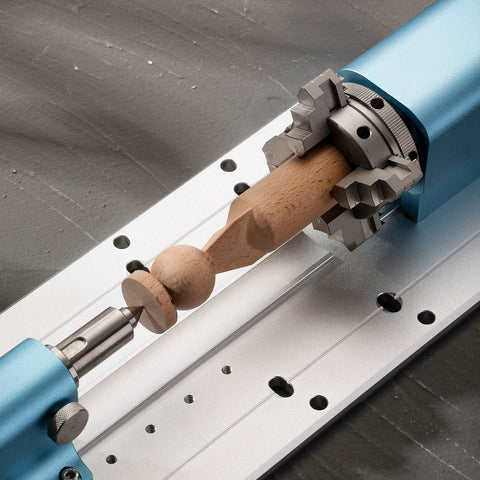

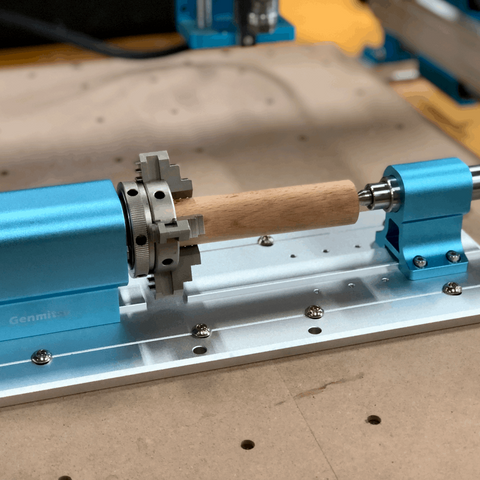

| Clamped Material Size | With Tailstock Length: 10-120mm, Without Tailstock Length: 10-200mm |

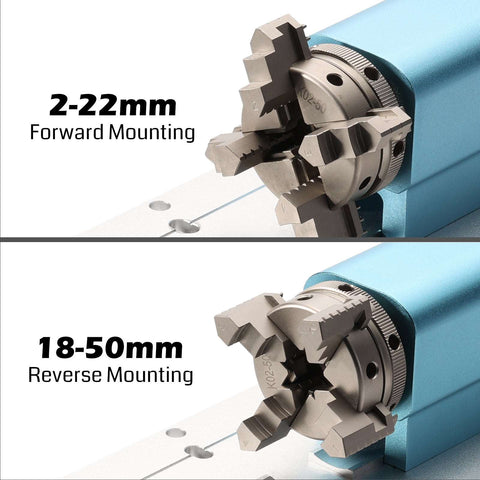

| Clamped Material Diameter | Forward Mounting: 2-22mm; Reverse Mounting: 18-50mm |

| Tailstock Spacing Adjustment | 5 installation positions, each position spacing is 20mm, and the range of adjustment is 10-120mm. |

| Tailstock Center Adjustment Range | 0-30mm |

| Direct Electric Motor | NEMA17 Planetary Geared Stepper Motor |

| Gear Ratio | 10:1 |

| Max Rotate Speed | 300°/S |

| Unidirectional Maximum Rotation Angle | 33512 x 360° |

| Center Height | 50mm |

| Size | 380 x 125 x 86mm (14.96” x 4.92” x 3.39”) |

FAQs

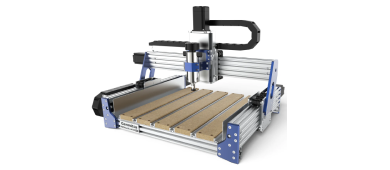

Q: Which machines can this 4th axis be compatible with?

A: Currently, it can only be used on 4040-PRO, 4040-PRO MAX, 4040 Reno and 3030-PROVer MAX CNC Router and needs to work with an offline controller to send the Gcode.

Q: Is this compatible with the PROVerXL 4030?

A: No, it is a true 4th axis, offering full functionality in XYZ and A axes and it requires the appropriate control board to operate. Please choose this rotary module specifically designed for the PROVerXL 4030 machine.

Q: What is the difference between a "true" 4th axis and a "fake" one?

A: A true 4th axis is a rotary axis that allows for continuous rotation, making it possible to machine complex curves and shapes accurately. A fake 4th Axis, on the other hand, is a simple indexer that can only rotate to predetermined positions.

Resource

Genmitsu 4th Axis Resource Page

- How to Reconfigure the 4th Axis Chuck

- Rotary Machining Guide

- How to Install Your 4th Axis and Square it on the 4040 CNC

- How To Zero-Out Your 4th Axis Project

- DeskProto 4th Axis Software Guide