What's a Hybrid Table?

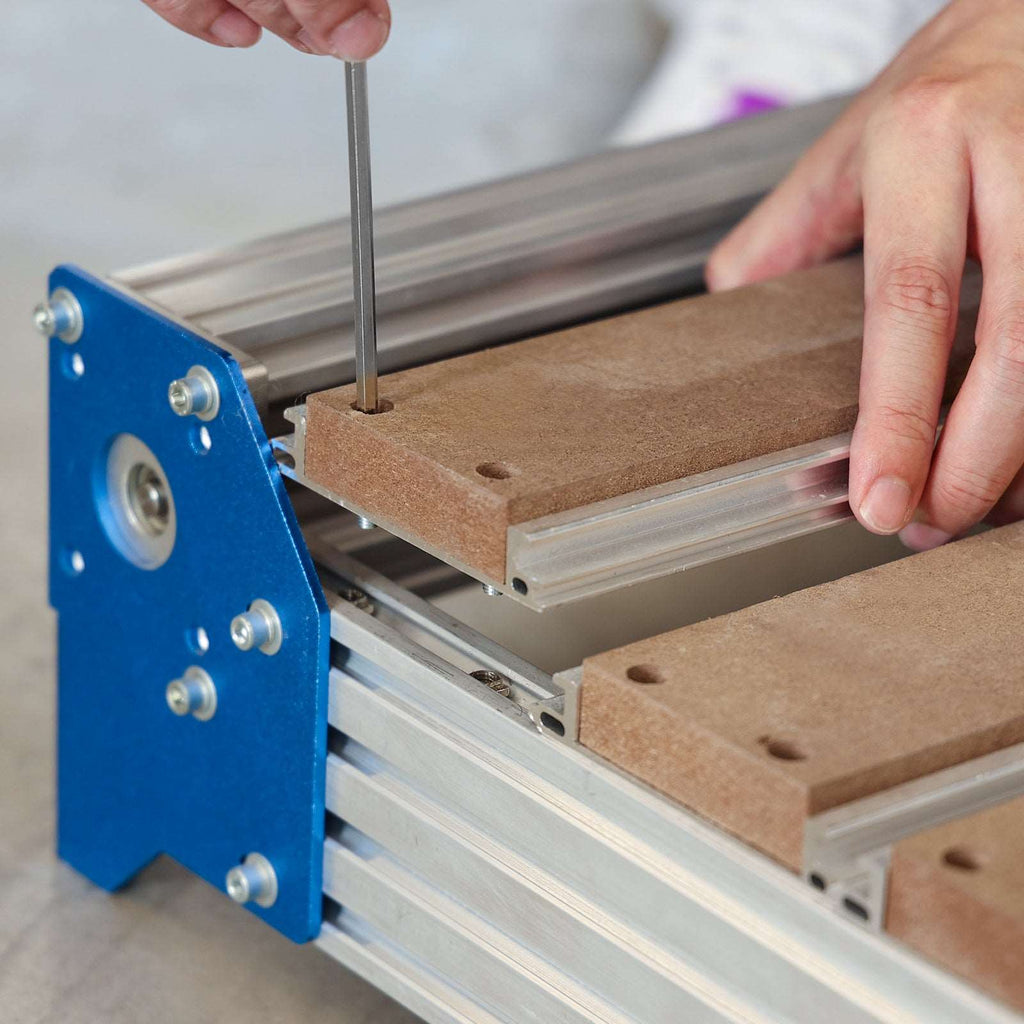

A hybrid table, also known as an Aluminum & MDF Hybrid table, is a revolutionary option for CNC machine users. It combines the durability of aluminum with the convenience of MDF (Medium-Density Fiberboard), offering the best of both materials.

Reasons to Use a Hybrid Table

Advantages

-

Enhanced Durability: The aluminum baseplate provides superior strength and can withstand heavy use. The T-track grid extrusions eliminate issues caused by moisture, ensuring long-lasting performance.

-

Easy Workpiece Clamping: The T-slot grid allows for secure and flexible clamping of workpieces, jigs, and fixtures. This makes it ideal for projects that require frequent repositioning or complex setups.

-

Cost-Effective Maintenance: In case of accidental damage to the MDF surface, you can simply mill the surface or replace a single MDF slat, saving both time and money.

Comparison with Ordinary MDF Board

When comparing a hybrid table to a regular MDF board, the hybrid table tends to be more expensive, and the aluminum layer limits customization options.

However, it is important to consider the disadvantages of MDF boards. Some notable drawbacks include:

-

Moisture Sensitivity: MDF material is highly susceptible to moisture, which can cause deformation, swelling, and loss of structural integrity.

-

Durability: MDF boards may wear out more quickly due to tool and workpiece contact, requiring more frequent replacement. This can be costly and wasteful.

Despite these disadvantages, MDF boards remain a popular and affordable option for spoilboards. It is essential to weigh the pros and cons and consider your specific needs before making a decision.

The Perfect Match: Genmitsu PROVerXL CNCs and Hybrid Tables

The Genmitsu PROVerXL CNC series offers the option to come with, or can be upgraded to, a hybrid table on three machines:

PROVerXL 4030 CNC Router Extension Kit

PROVerXL 4030 [V2] CNC Router (Hybrid Table Included)

PROVerXL 6050 Plus CNC Router (Hybrid Table Included)

This ensures that you can enjoy the benefits of a hybrid table right from the start or upgrade your existing machine effortlessly.

Comparison

| Hybrid Table | MDF Spoilboard | |

|---|---|---|

| Good |

|

|

| Bad |

|

|

2 comments

How can I get replacement brushes for my spindle motor 300 watt, 12-48 VDC?

Is the Hybrid Table available for the Genmitsu 3030-PROVer MAX? Or does the current one fit?