Written by Kitto

Laser technology has revolutionized diverse industries, from manufacturing and electronics to customization and art. Within this realm, fiber lasers stand out for their impressive capabilities and growing popularity.

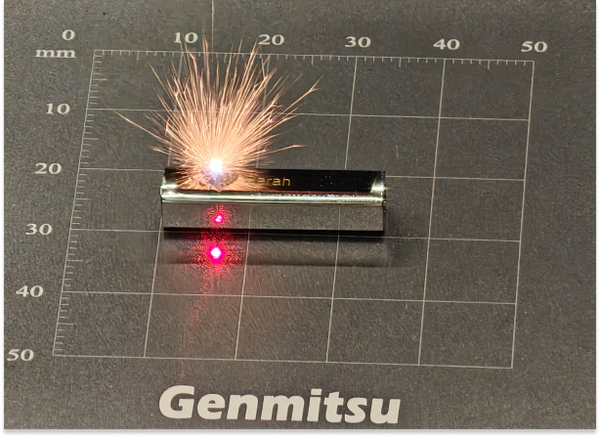

Today, we delve into the heart of a specific powerhouse: Genmitsu Z6, the 20W fiber laser. We'll explore its unique features, compare it to "normal" lasers (presumably diode lasers), and uncover its major applications, while also addressing a key limitation of certain laser setups.

What is a 20W Fiber Laser?

Imagine a laser beam pulsing with concentrated energy, guided by a flexible fiber optic cable. That's the essence of a fiber laser. Its core lies in the doped fiber that amplifies the laser light, resulting in an intense, highly focused beam. The "20W" denotes the laser's power output, indicating its ability to deliver 20 watts of power.

Key Advantages of a 20W Fiber Laser:

- Material Versatility: Unlike many "normal" lasers, which might struggle with metals, the 20W fiber laser's 1064nm wavelength is readily absorbed by metals, plastics, wood, stone, and more. This opens up endless possibilities for cutting, engraving, and marking diverse materials.

- Precision Powerhouse: The tight focus of the beam enables remarkably intricate and detailed work. You can achieve clean cuts and delicate engravings with minimal heat-affected zones, preserving the surrounding material.

- Blazing Speed: The high power translates to fast processing times. Compared to other lasers, you can finish projects significantly quicker, boosting productivity and efficiency.

- Durability and Reliability: Fiber lasers boast longer lifespans and require less maintenance, reducing downtime and overall operating costs.

- Compact and Efficient: The fiber optic design allows for a smaller footprint and efficient energy usage, making the 20W fiber laser a practical choice for various setups.

Comparing the 20W Fiber Laser to Diode Lasers

Diode lasers, widely used for engraving and cutting non-metals. While they are generally more affordable, they fall short in several key aspects:

- Limited Material Compatibility: Diode lasers often struggle with cutting metals effectively, restricting their range of applications.

- Lower Precision: The beam focus tends to be broader, resulting in less detailed work and potentially wider heat-affected zones.

- Slower Processing: Lower power output translates to slower processing speeds, increasing project completion times.

- Potentially Higher Maintenance: Shorter lifespans and higher maintenance needs can lead to increased operational costs over time.

Major Applications of the 20W Fiber Laser:

The versatility and power of the 20W fiber laser make it ideal for a wide range of applications, including:

- Metal Fabrication: Cutting, marking, and engraving on various metals for jewelry, electronics, automotive parts, and more.

- Electronics Manufacturing: Precise marking and component modification on delicate electronic devices.

- Plastics Industry: Cutting, marking, and engraving on plastic parts, toys, signage, and packaging.

- Woodworking: Intricate engraving and cutting for personalized gifts, signage, and decorative items.

- Medical Device Manufacturing: Precision marking and cutting for delicate medical instruments and implants.

It's important to note that while 20W fiber lasers offer a large degree of versatility and precision, there are limitations to consider depending on the specific setup. Where the laser beam is reflected by mirrors from a fixed position, achieving an expansive work area can introduce challenges. This is because the laser beam would hit the material at an increasingly oblique angle as the work area extends, leading to potential parallax issues and shape distortion. For applications requiring very large work areas, alternative laser setups, such as those with moving gantries or XY stages, might be more suitable.

The Genmitsu Z6 20W fiber laser represents a powerful and versatile tool, but understanding its potential limitations is crucial for making informed choices. Its superior material compatibility, precision, speed, and durability make it a compelling option for diverse applications, particularly when compared to the limitations of Diode lasers.

If you require a large work area, carefully consider the laser setup and its potential impact on precision and accuracy. By carefully assessing your needs and limitations, you can select the laser solution that best empowers your creativity and productivity.

![Review SainSmart PROVer XL Upgrades 4030 V2.1 [Part 2] Review SainSmart PROVer XL Upgrades 4030 V2.1 [Part 2]](http://www.sainsmart.com/cdn/shop/articles/Aspire-4030-proverxl-hardwarepoint-11-1024x768.jpg?v=1732883244)

![Review SainSmart PROVer XL Upgrades 4030 V2.1 [Part 1] Review SainSmart PROVer XL Upgrades 4030 V2.1 [Part 1]](http://www.sainsmart.com/cdn/shop/articles/SainSmart-PROVer-XL-V2-4030-tests-steel-titan-7075-36-1024x768.jpg?v=1732791855)

1 comment

What software does it use?