Written by Graham

This is a guide to the ER 11 collets and holders and their use on Genmitsu CNC Routers.

It should also be applicable to most CNC routers using ER11 collets.

The target audience here is a total novice using their first router. So if parts seem a little long winded to you then just skip the details.

What the ER 11 collet system is on your router and how to use it.

This is the ‘standard’ tool holder for small CNC routers. ER is the ‘name’ 11 means that it has an 11mm exterior collet diameter. The basic design goes back to 1973 and earlier.

Other sizes of collet are available using the same principles, these range from ER-8 to ER-50. These collets are NOT interchangeable being of different diameters.

Why is a collet system is used, why not just mount a chuck which would be more versatile and easier to adjust?

A Collet system will:

- Clamp the bit more firmly than a chuck.

- Give a better alignment of the bit within the holder.

The drawback is that the size of the collet used must be matched to the diameter of the bit shank, but different sized collets are relatively cheap.

It has 3 parts, Holder, Collet and Clamping nut:

Holder

Normally factory fitted onto the motor shaft as it should be a very tight or interference fit onto the shaft in order to keep it exactly aligned. It is further held by two grub screws tightened onto the motor shaft. It can be removed and replaced but will probably require heating to slacken the fit and the very careful application of force to avoid damaging the motor.

It has a tapered interior which matches the angle of the collet so that as the collet is forced into the holder the collet is compressed and clamps round the shank of the bit. A threaded area at the bottom to match the clamping nut and a couple of flats on the shaft allowing a spanner to be used to tighten and release.

Collet

The Collet fits round the shank of the bit and slides into the tapered interior of the holder. Near the bottom is a groove which fits into the clamping nut and at the bottom another taper which matches the clamping nut. The slots cut through the collet allow the segments to be forced inwards round the bit as it is tightened into the holder. There is obviously a limit to how much it can be compressed meaning the hole through the collet must match the diameter of the shank of the bit.

Nut

The nut which secures the collet into the holder is an A type which means it has a hexagon nut on the outside, other styles are available which will require different spanners but the interior will be the same.

It’s not just a simple flanged nut, the design of the interior is important.

At the base there is a bottom taper, this matches the taper angle of the bottom of the collet and ensures as it is tightened the collet is compressed evenly.

Above this is a retaining ring, this is very deliberately made wider at one side than the other. It’s not supposed to be concentric to the nut. This retaining ring fits into the groove of the collet. This holds the collet into the nut and also when you wish to remove a bit it forces the collet down out of the taper of the holder breaking any ‘cold welding’ which may have occurred and so releases the clamping round the bit allowing it to be removed easily.

The simple reason that the retaining ring is offset within the nut is to allow a collet to be inserted and removed.

Collet Sizes

ER11 Collets are described by the internal diameter. A 3mm collet is designed for a bit with a 3mm shank diameter. There is a bit of tolerance built in due to the clamping action so a 3mm collet should also take a 1/8” or 3.175mm shank. A 1/4” shank is 6.35mm so a 6mm or 7mm collet should work.

Depending on the bits you use get the collets to fit them, if you frequently use 6mm bits then get a 6mm collet, if you often use 1/4” bits get a 1/4” collet, if you use both, get both.

The maximum practical diameter of the shank of the bit using an ER11 collet is ~8mm.

Collets are also available in sets which can be cheaper and very useful if you also use drills. I use the SainSmart set.

As the collets snap into the nuts to make my life easier I also have purchased separate nuts for each collet size I normally use See here This is not necessary but makes my life easier.

Changing a collet

Removing a collet

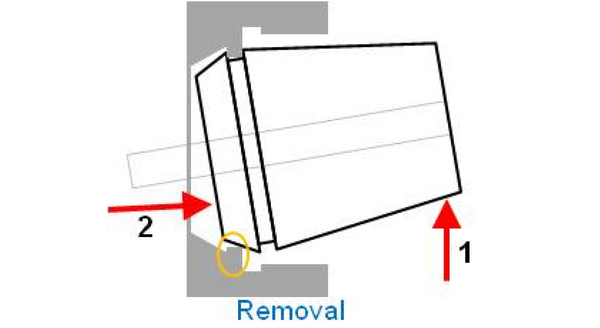

First remove any bit and unscrew the clamping nut completely from the holder. The collet now needs to be popped out of the retaining ring by pressing the collet over to the side (1) and then applying a push to pop it out (2).

It will depend on where the direction of the sideways push is. It will be easiest to push out when you are lifting the collet slot over the narrowest point of the retaining ring on the nut as shown by the orange circle. As you cannot see where this is if it doesn’t pop out at the first attempt rotate it a bit and try again.

Inserting a new collet

Before inserting a new collet make sure;

- The inside of the tool holder is clean and free from dust and debris.

- The collet itself is clean, on the outside of the tapers, in the spaces between the collet segments and in the bore which will take the bit.

- The nut is clean and free from debris around the retaining ring and on the bottom taper.

- Do not insert a collet into the nut with a bit inserted into the collet! This will limit the amount the segments of the collet can move and will make it nearly impossible to seat the collet into the nut correctly.

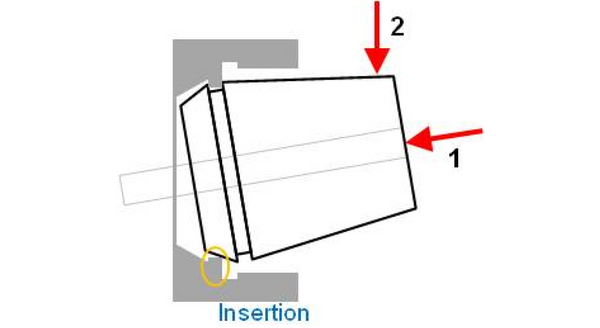

Locate the widest point of the retaining ring in the nut and engage the slot of the collet into it, while pushing it in to the nut (1) press it straight (2). After insertion check that the collet is straight and fully seated into the nut

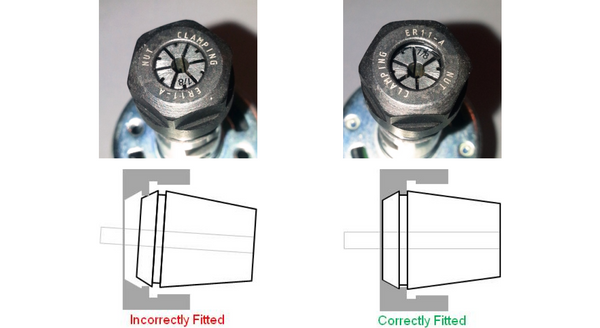

The left photo shows a correct alignment with the collet aligned with the nut and the bottom taper sitting on the corresponding part of the nut. On the right the collet is not aligned with the nut, the bottom taper is resting on the retaining ring rather than it being in the slot of the collet. When tightened from this position the collet will be forced out of alignment and damage to the nut, collet and tool holder could result.

Inserting a bit

- Make sure the nut is slack on the tool holder.

- Make sure the shank of the bit is clean.

- Slide the shank into the collet, the maximum depth of the bit the collet will clamp is ~18mm, some collets may have a shorter clamping distance. There is a gap between the top of the collet in the tool holder to the end of the motor shaft so a bit can be inserted further if required.

- Using the spanners firmly tighten the nut onto the holder, compressing the collet around the bit. This does need to be tight.

Checking everything

After mounting a bit, especially after changing the collet, manually rotate it and ensure the rotation of the tip of the bit is straight and true.

If it is not check:

- The collet is seated correctly in the nut.

- A dirty bit shank or collet interior is not throwing things out of true

- The tool holder taper and collet exterior are clean

- The collet is the correct size for the bit shank

- The collet has been tightened enough

- The bit is not bent